7/1/2019

(Written on 01/05/2023, but dated earlier to fit the chronological order of projects)

Longboards

My friend had an idea to make longboards in his garage. I joined him in this project since I liked making things. Neither of us knew how to ride a longboard, but we had the internet and we had the woodworking tools.

Since making these though, I've become an avid longboarder, and it's been a primary form of travel for me around university and in general.

We made about 5 different longboards, and sold a few to some other friends.

The Process

The gist of building a longboard from scratch goes something like this:

- Acquire wood

- We used 1/8 inch baltic birch plywood

- Cut wood into longboard-sized sheets

- Glue sheets together, alternating the wood grain (for strength)

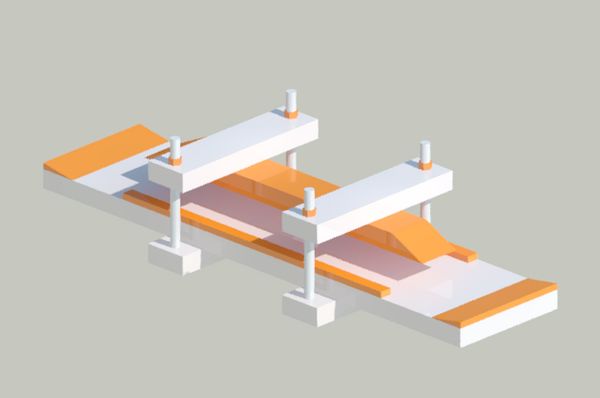

- Dry the glue and wood sheet stack while applying pressure to it

- This gives the longboard deck its "bend"

- You will want to make a contraption to hold the sheets in the right shape while it dries--a longboard press (see above)

- Once dry, cut and shape the pressed wood into a longboard looking shape

- Sand all the surfaces smooth

- Paint the back of the deck as you see fit and dry

- Drill the holes for the trucks/wheels

- Apply 3-4 coats of polyurethane to the whole board and dry

- This will ensure durability and waterproofing

- Apply the grip tape to the top of the board

- Mount the trucks

- You are done!

Closing thoughts

- More details can be found in our Google Docs engineering journal.

- This is one of my favorite projects, mostly because I'm still using the longboard!

- The total material cost for 1 longboard was about $60.00

- The majority of the cost were the trucks/wheels -- $35!

- 3 years later, the board is still in pretty good condition.

- I swapped out the wheels for those wavy shark wheels--they're not that different from normal wheels.

- Picture below.